Description

Weep Screed Flashing

Specifications

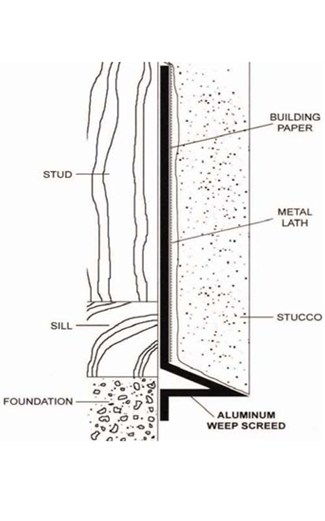

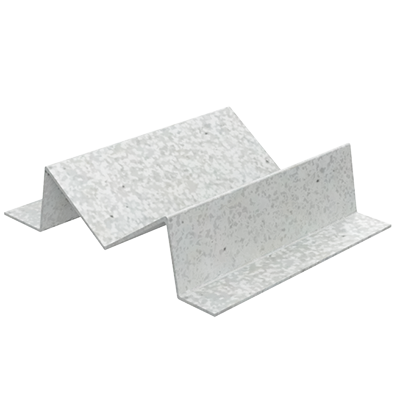

What is weep screed flashing

Required for (IBC Section 2512) cement plaster over framed walls.

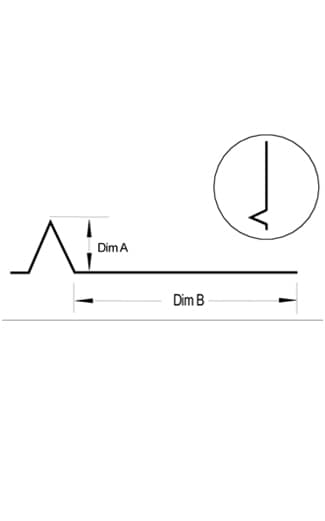

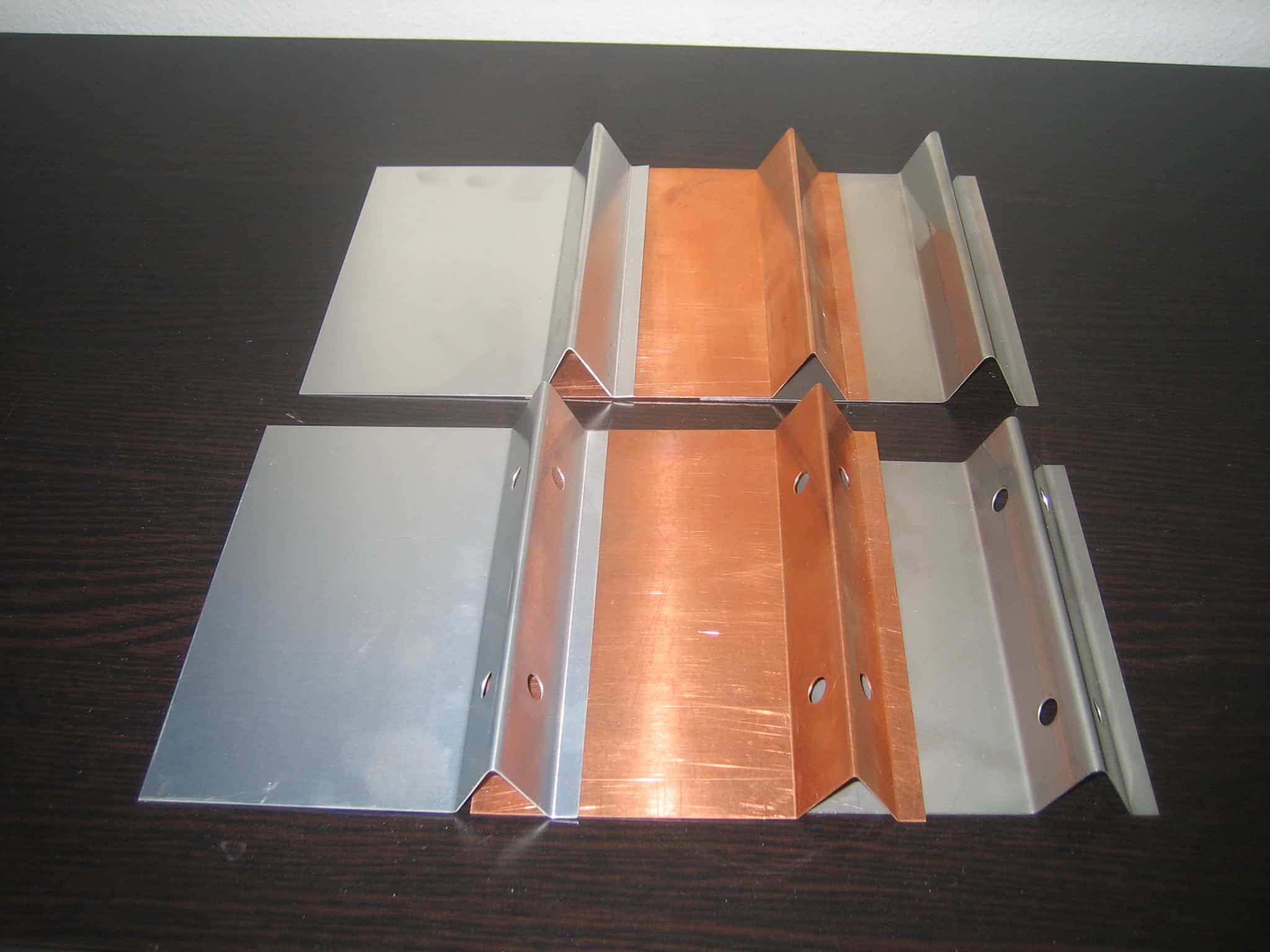

Set at or below the foundation plate line to allow moisture to escape or “weep” out and to prevent ground moisture absorption.. The weep screed is available in the following materials: galvanized, Stainless, Copper, 040 aluminum . The weep screed may be a V nose (as shown) or a casing bead style with holes for drainage.

The attachment flange should be at least 3 ½ inches in height and the bottom of the attachment flange must be below the plate line. The nose of the weep screed should be 4 inches above ground. The water-resistant barrier should lap over the attachment flange of the weep screed by a minimum of 2 inches. The weep screed is installed along runs and overlaps each other. If they are abutted, the vertical joint between attachment flanges should be covered completely by the water-resistant barrier. Weep screed flashing isn’t required for masonry or concrete substrates.

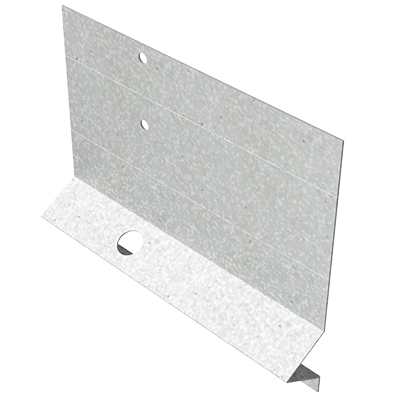

Weep Screed Flashing also Aluminum version of the F.H.A. approved standard weep screed with a 7/8″ ground and 3-1/2″ nail flange for 3-coat plaster. Also available in custom break formed sizes and a variety of materials: Copper, Stainless Steel, G90 Galvanized steel.

Compare to: FWS, WS

PRODUCT SUBMITTAL SHEET: (Click on the PDF logo above)

MATERIAL: Aluminum Alloy 5052 H32. Also available in 16 oz copper, 26 ga Stainles Steel and 26 ga Galvanized G90 steel.

THICKNESS: Aluminum – nominal .025

LENGTH: Standard 10 ft.

FINISH: Standard- ‘Mill’ finish

OPTIONS: Please also see our Custom Brake Shape section for more information on custom weep screeds including: optional materials, various ground sizes and offset weep screeds.

Also check out DIAMOND FURR: CONVEN. 7/8″ – WEEP